-40%

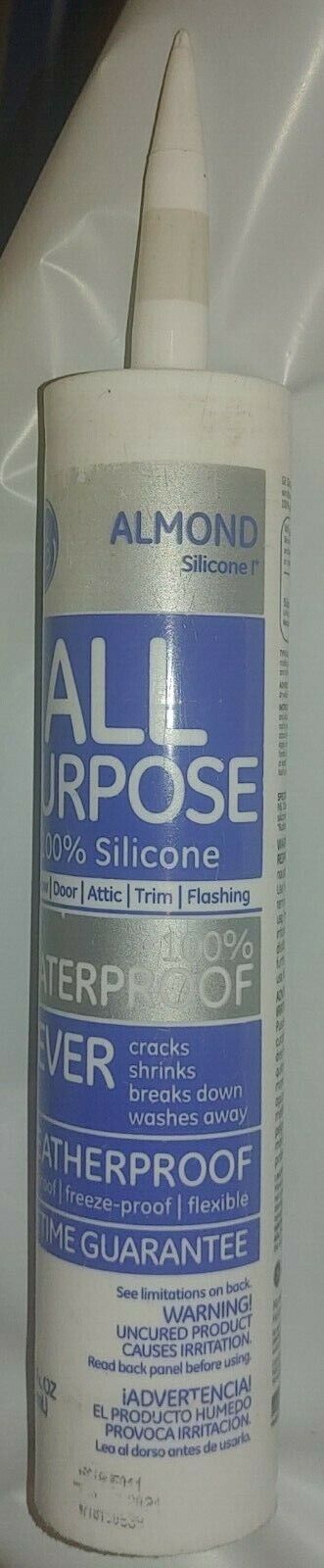

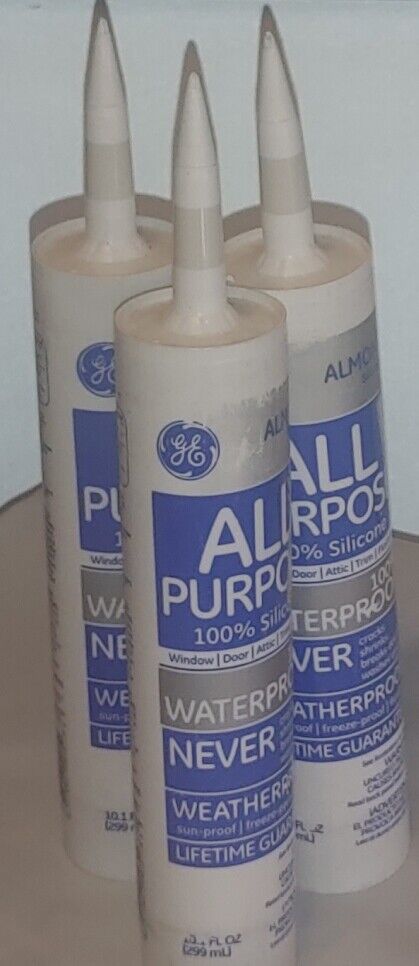

GE Silicone 1 Almond Silicone I All Purpose Caulk Sealant & Adhesive 10.1 oz

$ 6.96

- Description

- Size Guide

Description

GE Silicone 1 Almond Silicone I All Purpose Caulk Sealant & Adhesive 10.1 ozGE Silicone 1 Almond Silicone I All Purpose Caulk Sealant & Adhesive 10.1 oz

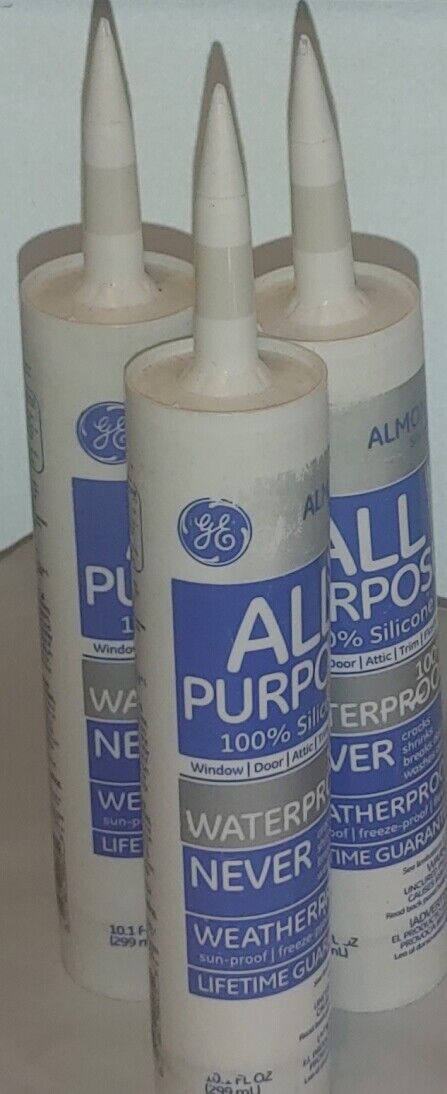

Buy more to get the discount, these are new and unused.

As their selling claims, "All Purpose Silicone 1 sealant is 100% waterproof and ideal for a wide range of projects exposed to harsh weather from the attic to the basement. Permanently flexible, it can stretch and move with expansion and contraction and will never break down due to ultraviolet rays or freezing temperatures. This high-quality sealant is resistant to unsightly stain causing mildew growth. It’s easy to apply and offers excellent adhesion to many common building materials including most wood, metal, vinyl siding, drywall/plaster, glass, and plastic. Backed by a lifetime guarantee."

Attributes:

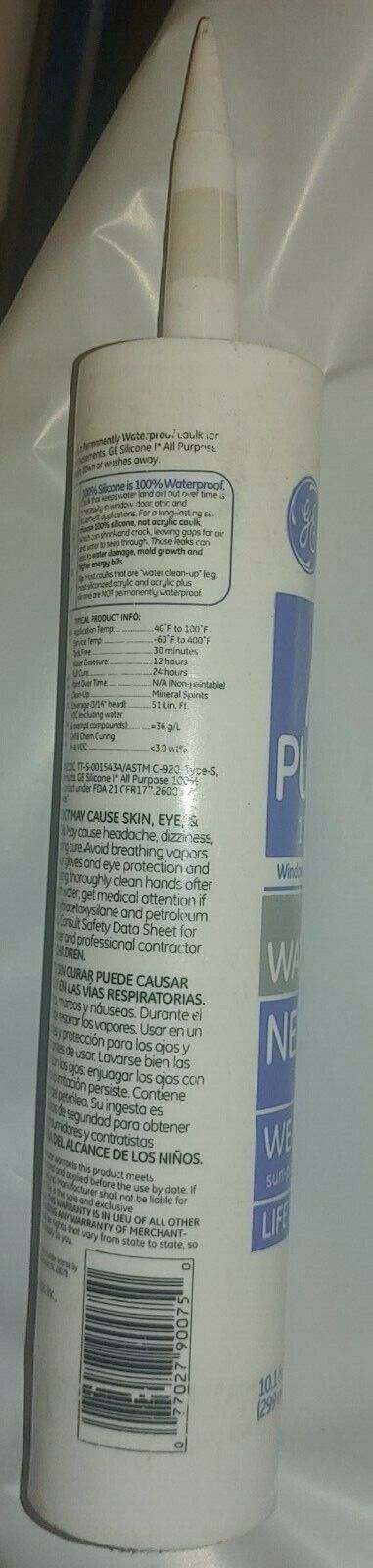

Resists mold(1) with 7-year mold-free product protection

Same-day rain and water-ready

Full cure in 24 hours

100% silicone is 100% waterproof and 100% weatherproof

Sun-proof and freeze-proof

Meets ASTM C-920 Class 25 specifications

Permanently flexible

Never cracks, shrinks, breaks down, or washes away

Freeze/thaw stability

Non-paintable

Basic Uses: All Purpose Silicone 1* sealant is used in a wide variety of applications including, but not limited to, windows, doors, siding, trim, and vents, as well as attic/basement applications.

Adheres To: Common building materials including most metals and woods, aluminum, composites, brick, stone, stucco, masonry, cement board, glass, porcelain, ceramic tile, drywall, plaster, vinyl siding, PVC, fiberglass, and painted surfaces.

Masking: The use of masking tape is recommended where appropriate to ensure a neat job and to protect adjoining surfaces from over-application of sealant. Masking tape should be removed immediately after tooling the sealant and before the sealant begins to skin over (tooling time).

Instructions:

1. Remove dirt, grease, moisture, soap residue & old caulk from area to be sealed. Use backer rod for gaps larger than 1/2” x 1/2” (12.7mm x 12.7mm) (Sealant depth should be controlled with a closed cell, non- gassing type backer rod. Backer rod should be slightly larger in diameter (25 to 50%) than the joint width.)

2. Cut nozzle to obtain desired bead size.

3. PIERCE INNER FOIL SEAL.

4. Using caulk gun, apply sealant into gap. Smooth the sealant into gap.

5. Wipe hands & tools thoroughly before washing.

6. Allow a mimimum of 12 hours before exposing sealant to water.

Sealant Application

Apply sealant in a continuous operation, applying a positive pressure adequate to properly fill and seal the seam, cavity or joint.

Tool or strike the sealant with a concave tool, applying light pressure to spread the material against the joint surfaces to ensure a void-free application.

When tooling, use care not to spread the sealant over the face of the substrates adjacent to the joint or masking as the silicone can be extremely difficult to remove on rough or porous substrates. Excess sealant should be cleaned from glass, metal and plastic surfaces while still uncured. On porous surfaces the excess sealant should be allowed to progress through the initial cure or set-up. It should then be removed by abrasion or other mechanical means.

If sealant is applied when the temperature is below 32°F (0°C) or if frost or moisture is present on the surfaces to be sealed, the rate of cure will slow. For standard cure speed, apply in temperatures above 32°F.

The cure rate of this product is dependent upon temperature and the availability of atmospheric moisture. Under average conditions (relative humidity of 50 ±5% at an air temperature of 73.4 ±2°F [23 ±1°C]) this material can attain a cured thickness of 2-3 mm per 24 hours (assuming ample access to atmospheric moisture). As temperature decreases, the cure rate slows down (and vice versa). Low moisture environments will also reduce the cure rate. Near-confined spaces, which limit the overall access to atmospheric moisture, will generally allow cure only at that surface which has access to the atmosphere.

Thanks for browsing.

Check out my other auctions,

from my other accounts.

(Shipping prices include insurance, I offer different methods, check to make sure you're getting the best one, and ask me for combined shipping discounts.)

Items come from a smoke free, pet free house.